Record Lathe Cutterhead V3

März 2016

Inhaltsverzeichnis

- Prototyp

- Vorschubmechanik

- Cutterhead V2

- Cutterhead V3

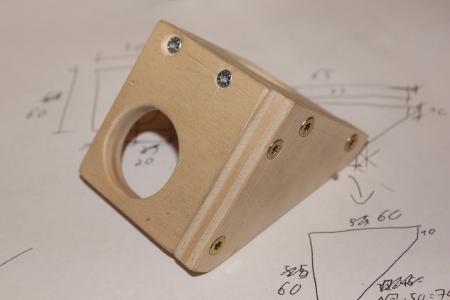

Mit dem Ziel den Cutterhead deutlich kleiner zu bauen, um die Auslenkung der Nadel direkt auf die Nadelspitze zu übertragen und gleichzeitig Eigenschwingungen an der Nadel zu minimieren, fing ich an ein passendes Gehäuse aus etwas Restholz zu bauen. Die Löcher haben einen Durchmesser von 30mm, die Hochtöner werden von aussen angeschraubt.

Die Nadel (hier etwa 1,2mm dicker Stahlzusatz) wird schräg durch ein Loch in einem Aluminiumstab gesteckt und von vorne mit einer Gewindeschraube fixiert. Hinten ist eine V-Förmige Feder aus dem 3D Drucker angeschraubt, welche die Nadelhalterung an der Hinteren Platte des Gehäses hällt.

Auf die Membran der Lautsprecher sind zwei 3D gedruckte hohle Kegel angeklebt. Sie übertragen die Schwingungen auf ein kurzes Stück Messingdraht. Zwei weitere Messingdrähte (0.8mm) sind 90° zueinander in die Aluminiumhalterung eingeklebt und werden mit den Drähten zum Lautsprecher hin durch Lötzinn verbunden. Dadurch lässt sich das ganze bei Bedarf zerlegen, ist aber ausreichend fest fixiert um die hohen Frequenzen zu übertragen.

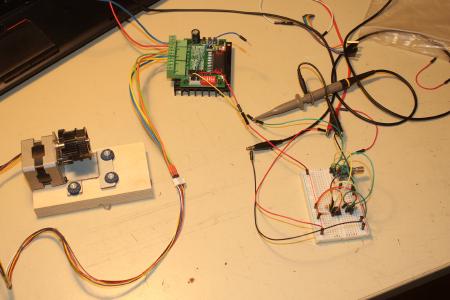

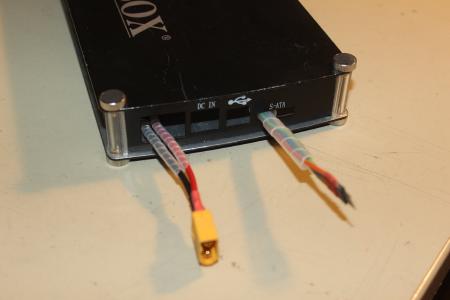

Die Schrittmotorsteuerung musste auch mal etwas einfacher aufgebaut werden. Zuvor musste ich immer einen Rechner angeschlossen haben, um die Geschwindigkeit einzustellen. Aber es geht doch viel einfacher; ein fertiger Schrittmotortreiber+NE555. Der NE555 ist als astabile Kippstufe aufgebaut. C1 hat einen Wert zwischen 10nF und 100nF. Das Poti R2 und den Festwiderstand R1 hab ich durch austesten auf den benötigen einstellbaren Frequenzbereich ermittelt.

Die Endgeschwindigkeiten am Cutterhead lassen sich nun von ca. 4mm/min bis 12mm/min einstellen. Mit 8mm/min Vorschub hatte ich zuvor nie probleme.

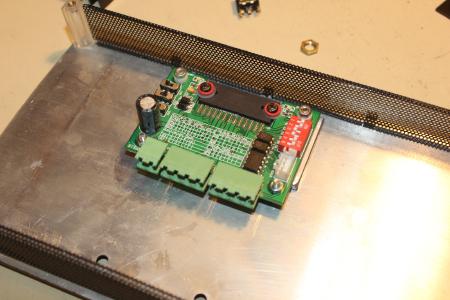

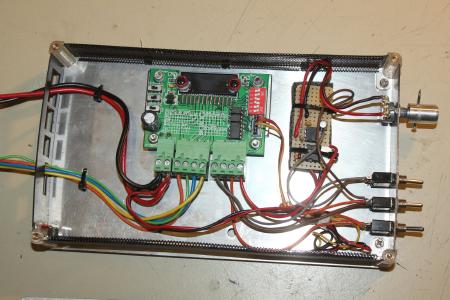

Das Ganze passte optimal in ein altes externes Festplattengehäuse.

Den Schrittmotor hab ich mal aus einem alten Scanner ausgeschlachtet. Durch das fest montierte Getriebe ist er für solch langsame Bewegungen super geeignet. Allerdings liegt die Drehfrequenz für 8mm/min Vorschub genau in dem Resonanzbereich der Plastikzahnräder, was ein unausstehbares Scheppern mit sich führt.

Einerseits könnte ich die Gewindestange von M8 auf M10 oder 12 ändern, oder aber die Übersetzung anpassen. Aus selbigem Scanner stammt das obere Zahnrad inklusive Riemen, den ich etwas kürzen musste. Nun scheppert das Getriebe nurnoch bei sehr langsamen Vorschub <6mm/min.

Zuvor war der Schlitten durch einen Holzblock mit eingepresstem Gewinde mit der Gewindestange verbunden. Das war natürlich hochgradig provisorisch und wurde nun durch einen quadratischen Stahlstab mit angeschweisster Gewindemutterhälfte ersetzt. Die beiden Holzblöcke links und rechts lassen sich nach wie vor im Abstand einstellen und erlauben ein nahezu spielfreies aufliegen des Hebels.

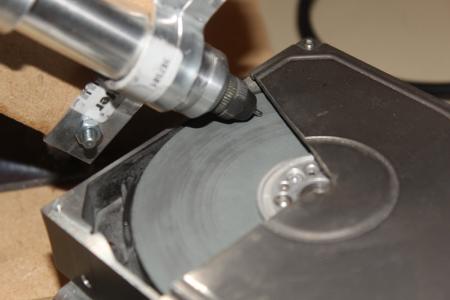

Wie bereits beim HDD Tellerschleifer ergänzt hab ich den Dremel durch eine Proxxon LSB/E ersetzt. Mit der neuen Lagerung aus einer Festplatte ist das Nadelschleifen nun runder und genauer.

Nun konnte weitergeschnitzt werden. Die Nadel hier ist eine 1.5mm Wolframelektrode geschliffen auf ca. 70°. Wie immer 45rpm auf einer CD. Für ein 5 Minuten langes Lied musste ich bis auf 36mm/5min = 7.2mm/min Vorschub runter, damit es auf die CD passt.

- Der Song ist T & Sugah x NCT - Stardust (feat. Miyoki): Erstellt am 6.11.2016, Download als mp3 oder wav

So ganz bin ich mir noch nicht sicher, wie spitz die Nadel sein muss. Auch beim Gewicht beim Schneiden bin ich mir noch nicht einig. Bisher waren es immer 100g +- 30g.

Verglichen mit den vorherigen Aufnahmen mache ich aber Fortschritte, oder?

Wer Erfahungen, Tipps, whatever dazu hat; schreib mir Bitte: interfisch@gmx.net Fragen natürlich auch ;)