Record Lathe Cutterhead V2

Januar 2014

Inhaltsverzeichnis

- Prototyp

- Vorschubmechanik

- Cutterhead V2

- Cutterhead V3

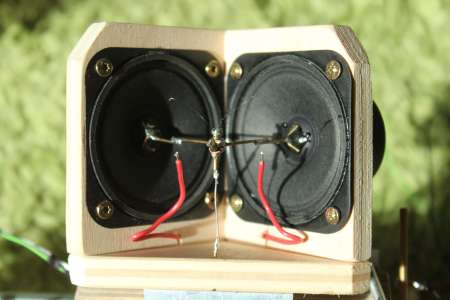

Als Lautsprecher für einen DIY Cutterhead sollen Hochtöner besser geeignet sein als Breitbandlautsprecher, da durch die invertierte RIAA Kurve die tiefen Frequenzen eh gedämpft werden.

Bei Pollin sah ich dann die Hochton-Lautsprecher OT-57-148 und hab mir für den Preis einfach mal zwei bestellt.

Da diese Lautsprecher mit ihren 53mm Einbaudurchmesser viel kleiner sind als die PC-Boxen konnte ich direkt einen neuen Cutterhead entwerfen.

Der Einfachheit halber wieder aus Holz (Sperrholz). Die Form der drei Teile hab ich ausgefräst. Ist aber ansich nichts kompliziertes dran.

Die Bewegungsübertragung geschieht über, mit Epoxy auf die Membranen angeklebten, 1mm Messingstangen. Die Nadel wird wieder von einer Lüsterklemme gehalten. Die einzelnen Drahtstücke und die Lüsterklemme sind zusammengelötet, dadurch können durch kurzes Erhitzen die Abstände nachträglich angepasst werden.

September 2014: Neue Nadeln

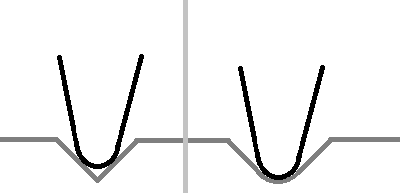

Die Nadeln die ich bisher verwendet habe waren meist per Hand irgendwie zurechtgeschliffen. Idealerweise sollte aber die “Schneidnadel” spitzer sein, als die Nadel am Tonabnehmer, sodass die Nadel beim Abspielen an den Wänden aufliegt und nicht im Tal rumeiert (siehe nachfolgende Skizze).

Links: Die Nadel wird von den Rillenwänden geführt und folgt somit exakt der Spur. Rechts: Die Schneidnadel ist zu stumpf, sodass die Nadel beim Abspielen am Boden der Rille aufliegt und sich freier bewegen kann.

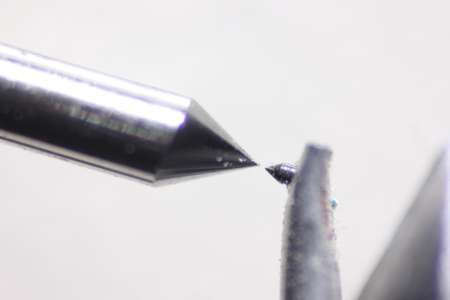

Um ein Stück Stahlstange möglichst Spitz zu schleifen, hab ich einen Tellerschleifer aus einer Festplatte gebaut inklusive Nadelschleifvorrichtung.

Hier das Ergebnis unter meiner Kamera mit Retroadapter. Die Stange (links) hat einen Durchmesser von 1,5mm (es war mal eine Nähnadel). Nach ein paar Sekunden Nassschleifen ist sie schon mindestens so Spitz, wie meine Ortofon Nadel (Die müste so etwa 25µm an der Spitze haben). Die Nadel hab ich einfach mal auf 60° geschliffen, keine Ahnung ob das taugt.

Dann wollte ich auch mal hören, ob die neue Nadel auch was gebracht hat.

Damit die Nadel das harte CD Polycarbonat besser wegdrücken kann hab ich mit einem Fön für etwas Temperatur gesorgt. Nach dem Vorbild der Presto Cutterheads ist die Nadel etwa 65° nach hinten gelehnt.

Leider musste ich die Nadel etwas weiter aus dem Cutterhead herausstehen lassen, da dieser mit dem (hier) linken Lautsprecher sonst an den Pin vom Plattenteller stößt. Das wird noch verbessert werden!

Das Auflagegewicht hab ich bis auf 43 Grammm reduziert um dem Quietschen zu entgehen.

45 RPM, 8 mm/min Vorschub, und den Song “Grapes - I Dunno” durch Audacity mit Hochpass 150 Hz, Tiefpass 15 kHz und inverted RIAA geschickt.

- “Grapes - I Dunno” 7.9.2014 (mp3) bzw. als wav

Ein bisschen mehr hatte ich mir zwar schon erhofft, aber es gibt ja noch so vieles zu verbessern.

Weiter mit dem Cutterhead V3