Project start: August 2015

Microquad

Motors and the electronics are getting more and more tiny. Especially flying and racing miniquads is quite different with smaller copters.

For that reason, I've decided to build my second miniquad with 3" propellers and design it as small as possible.

First the parts I choose:

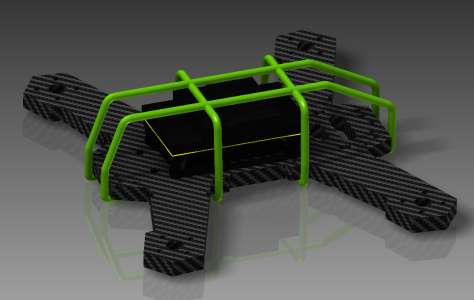

I started by roughly drawing the shape of the frame and laying out the electronics.

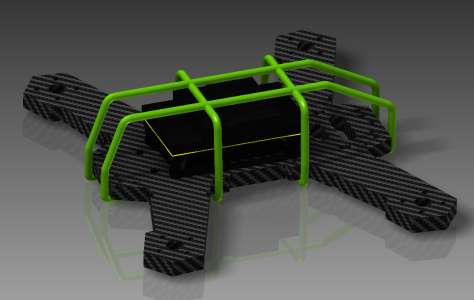

With an idea in mind I started designing in Inventor. Instead a typical topplate I wanted to build something else, like an aluminium cage.

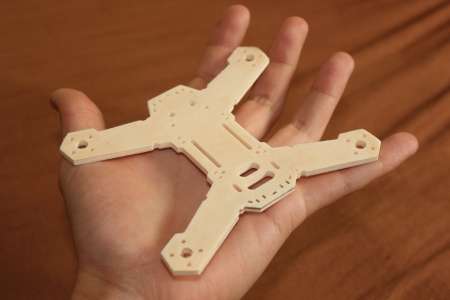

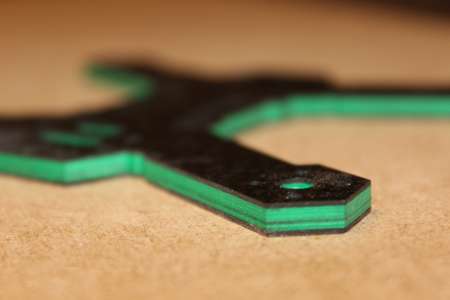

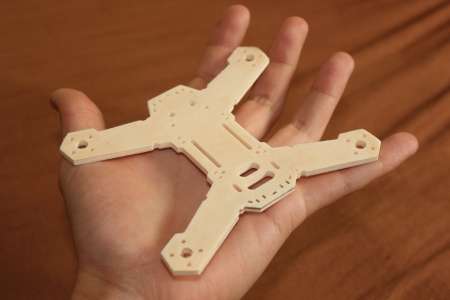

It's always a good idea to have a prototype at hand before building the final thing.

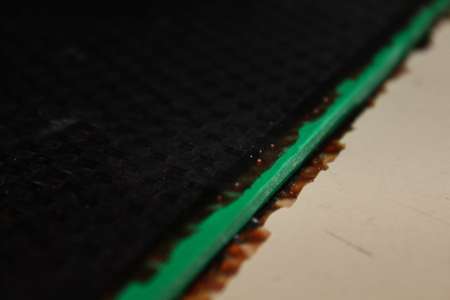

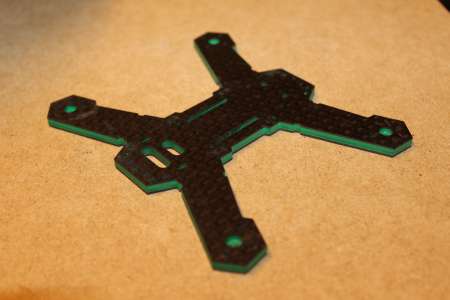

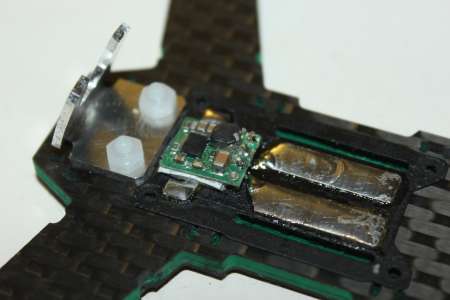

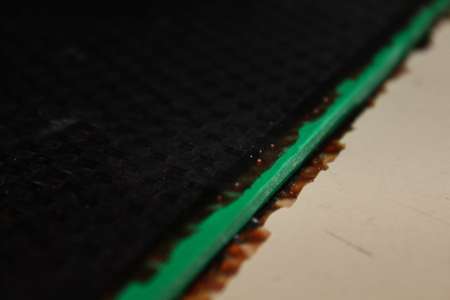

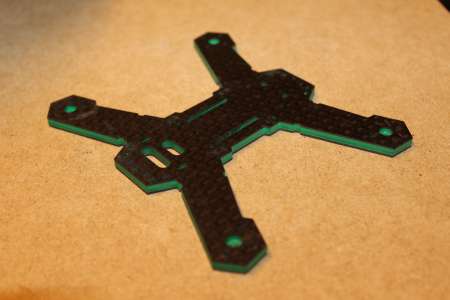

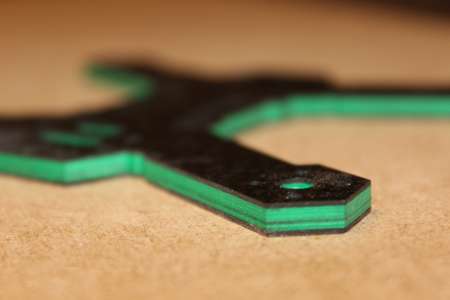

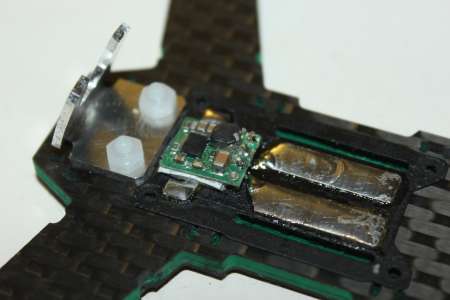

Since the frame is going to be made out of one single piece, some tough material was needed. Instead of using 5mm thick carbon I decided to go for a carbon pvc foam sandwich. It is cheaper, lighter and looks way cooler. Both CFK sheets are .7mm thick, so with the 3mm PVC Foam it's 4.5mm.

The glue I used was WEICON RK-1500. At this point a big thanks to Pascal for the glue and cnc milling.

Some slots for the cable ties are only 1.2mm wide and needed to be first milled with a <=1.2mm milling bit. The circles unter the motor shaft are milled as pockets, so if a snap ring falls of it doesn't get lost. This saved me a flying day on my miniquad.

By the way, all the files can be found at the bottom of this page.

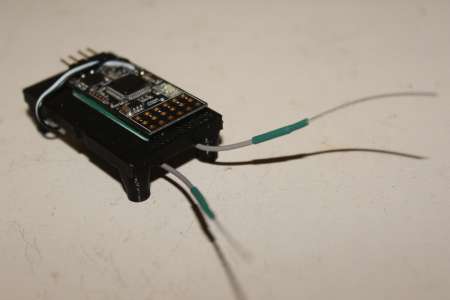

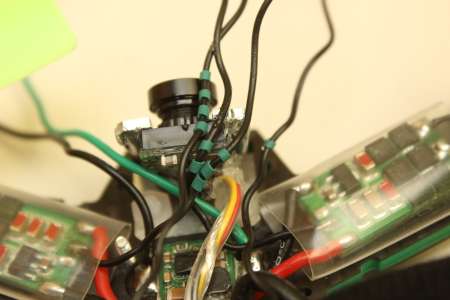

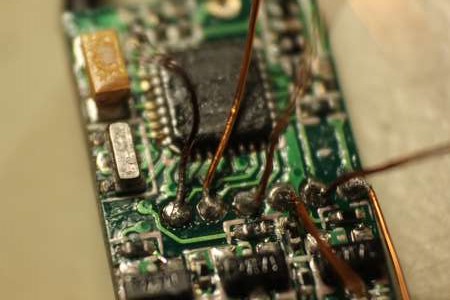

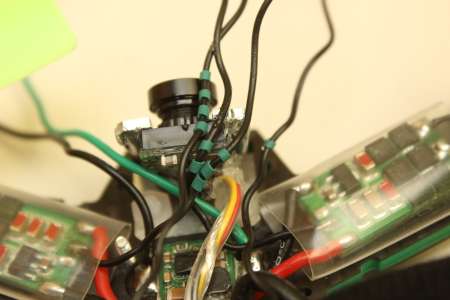

It's hard to see on those pictures, but this thing is really tiny. Even the sma connector is way to big and with the antenna mounted it would stick out quite far. Therefore I replaced the sma connector with a U.FL connector, wich is better suited for this kind of application. Also, a normally preferred cloverleaf antenna is wider than the whole frame and would not survive many crashes. So I build an oldschool dipole.

Quarter Wavelength = 1/4 * c/f = 299 792 458/5866000/4 = 12,78mm.

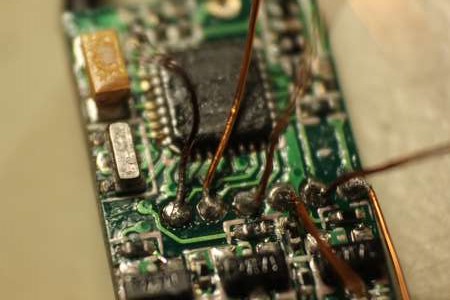

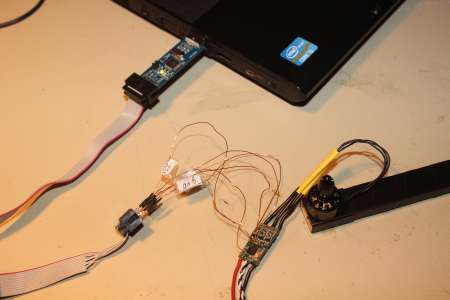

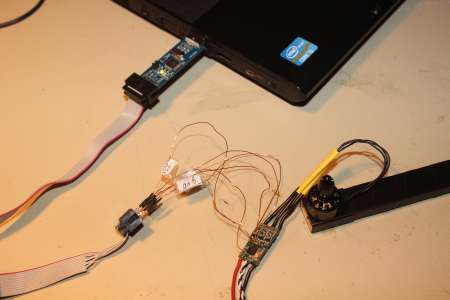

Next reflashing the DYS SN16A ESC's, wich were a bit cheaper than the BL16A. I don't have a problem flashing the BLHeli bootloader via ISP, so saving a few cents was worth it.

Pad assignemnt from left to right: MOSI, MISO, SCK, GND, 5V, RST

Every ESC was labeled inside BLHeli Suite and labeled with the corresponding number of marked capacitors on the ESC itself.

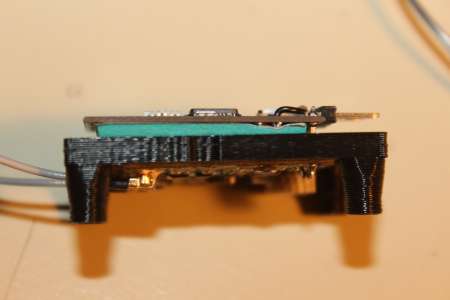

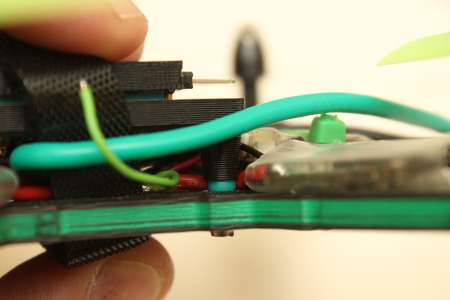

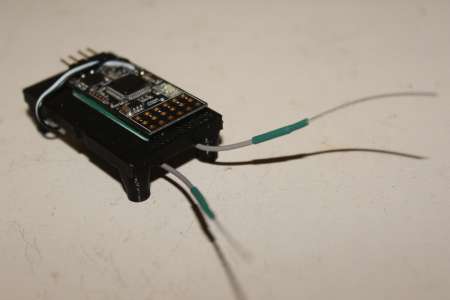

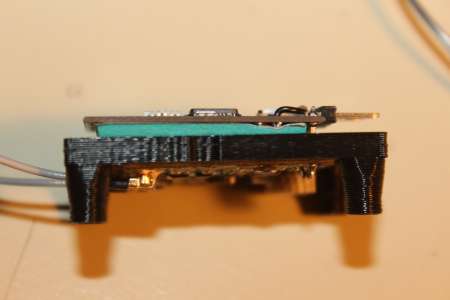

As I said before, theres not much space on the frame. The receiver, a bare D4R-II, is flush-mounted to a 3D printed "table". Because of pure skill the singal, 5v and ground pins are perfectly lined up with those on the Afromini Flight Control and were soldered directly onto each other. Again .5g saved, yeeha.

5V, GND, TX and RX stick straight out to the back for programming later on.

With some foam rubber as spacer and double sided tape the Flight Control is held in place. Later, I put a printed cover on top of it and strapped it all together with one cabletie.

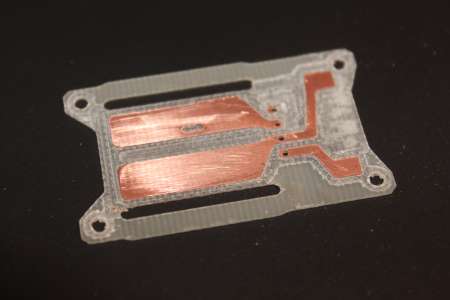

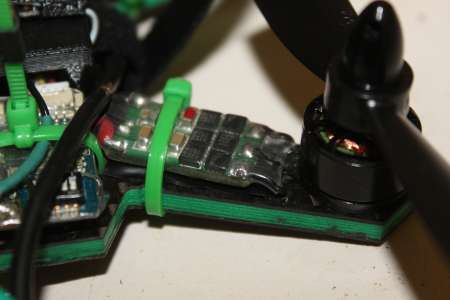

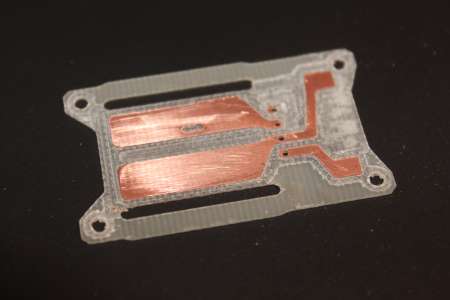

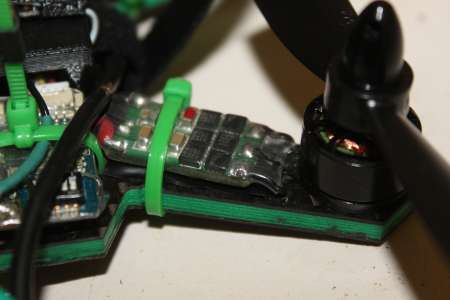

CNC milling brought me this beautiful looking PDB. The LiPo and all four ESC's are going to be soldered to the two big pads. The four holes are there for soldering the Pololu Stepdown to get ground and 5V on the smaller pads.

Because everything gets a green black coloring, the PDB needed to be spraypainted in black.

The camera is also very small and hasn't got any kind of mounting point. The easiest way for me was to mill a aluminium bracket in where the camera gets hotglued in.

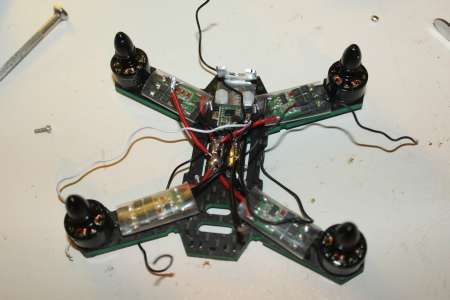

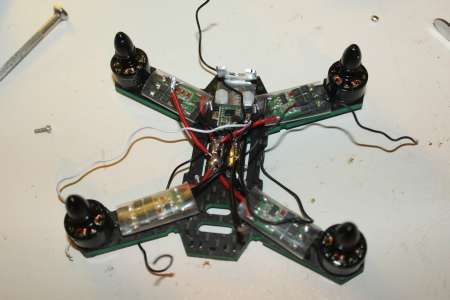

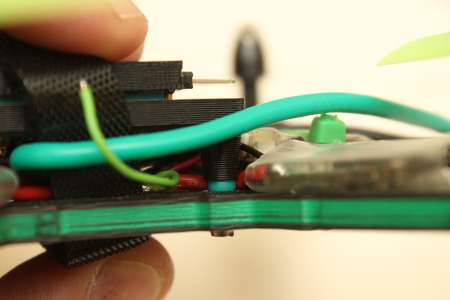

Now everything can be soldered together. To stay faithful to the choosen colors, I used green (with a touch cyan) silicon wire (16AWG).

The signal wires from the esc's (black instead of white) are marked with some small shrink tubing at the ends.

M2 screws are screwed from the bottom up trough the plastic holder.

Besides the motors and the plastic in the middle nothing else uses screws, only lots of green and black cable ties.

After bending four rods of 2.4mm thick aluminium filler material, those were mounted with cable ties right at the small slots in the frame.

Later, two Velcro Tapes will hold the lipo in place. The Nano-tech 4S 850mAh are a bit bulkier as exprected.

For now, I'm going to use 3" cut down Gemfan 5045 props. With 4S the copter drews 23.5A at full throttle, 7A at half throttle.

Also I replaced the black M4 aluminium nuts with some M4 self-locking flange nuts.

Flight time is around 7 minutes. I'm hoping to able to anodize the aluminium parts green in the near future.

Sadly, I wasn't able to get the buzzer on the afromini to work so I had to fly without a discovery buzzer and fly with a seperate lipowarner. (Apparantly I'm not the only person having this problem:

AfroMini 32 fc, discussion and setup)

The days before the maiden flight we had some rain here, so the fresh cut gras was sticking very well.

Maiden Flight

Files

DXF and STL Files:

Version 20150926

Settings and PID Dump